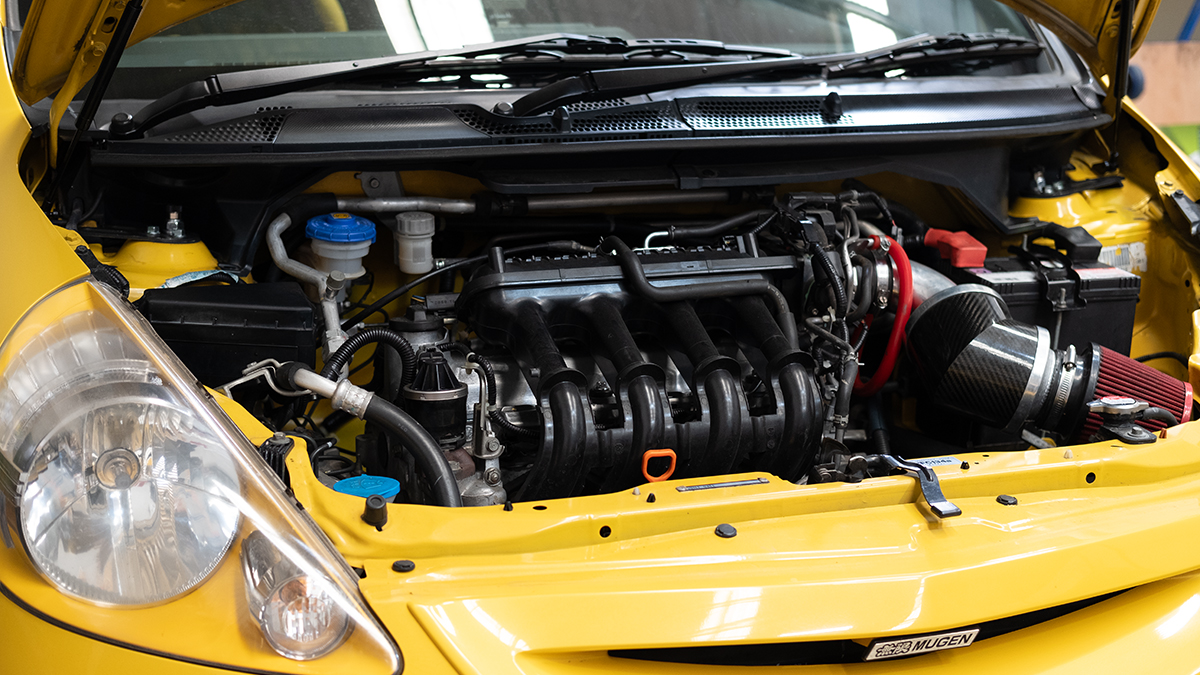

Following on from an earlier blog post about improving the driver ergonomics of the Honda Fit/Jazz for track driving, this time we’re turning our attention to the possibly more exciting area of extracting greater performance.

DRIVETRAIN

Due to its focus on fuel economy, the Fit/Jazz manual gearbox comes with a very short first gear. This gets the car moving easily, but all other ratios are relatively long, which might help lower your running costs but leaves a lot to be desired at the track.

Taking into account the top speeds reached at each of our local tracks (if a six-hour round trip to Winton can be classified as ‘local’), we sourced a spare L15 gearbox (try doing that with a B- or K-Series in 2024) and ordered a new final drive from Mfactory.

This shortened the final drive ratio from the factory 4.29:1 to 4.9:1 as well as a JUN lightweight flywheel that shed 3.1kg (7.3kg to 4.2kg).

We took this opportunity to send the box off to a local Honda gearbox specialist to replace all seals and bearings and perform the final drive install.

The results were instantly satisfying, though not surprising. There’s a reason Honda’s Type R models have vastly different final drives to the base models.

On track, this translated to improved acceleration and higher corner exit speeds without limiting the top speed (because of the length of the straights).

SUSPENSION

Having had plenty of success with more popular Honda platforms, we investigated where we could improve the (very low) Fit/Jazz for high performance driving with a range of suspension changes.

The first step was to work out the car’s basic attributes, these being the corner weights and front and rear suspension motion ratios.

With these in hand we could work backwards from our target ride frequencies to determine our spring rates.

In our case, the front and rear corner weights used for calculation were 280kg and 160kg, and the motion ratios were 0.9 and 0.65, respectively.

We chose to target a front ride frequency of 2hz for the front and 2.2hz for the rear, as it’s important to have a slightly higher rear ride frequency, resulting in the choice of spring rates of 6kg/mm front and 8kg/mm rear.

On its first outing the car proved to do everything asked of it on track, with good rotation when called for. The stiffer springs helped deal with the cornering and braking forces of the tyres better than the previous Tein coilovers, which used 4kg/mm front springs and 5.5kg/mm rear.

To improve the alignment we designed our own version of the front strut top, one that provides additional caster (+1°) and camber (-1°) and is used in conjunction with a pair of camber bolts to achieve our target total camber.

The Honed GD3 Strut Top also uses a high-quality spherical bearing and is designed to allow for additional bump travel on lowered cars.

At the rear, shims were developed to adjust the rear camber and toe alignment settings. In its unmodified form, our car didn’t have sufficient rear camber and the rear toe was toe-in to an excessive degree.

The Honed Rear Alignment Kit was created to address these things.

RELATED POSTS

EK AC Duct Block-Off Parts – 3D Print Files Download

EK AC Delete Duct Block Off Parts – 3D Print Files Free Download

EK Civic Update Engine Rebuild

Project update and details from Honed’s D16 Turbo EK.

Prop Valves and Bias Bar Adjustment Explained

Post explaining how a proportioning valve works and what a bias bar does to the relationship between front and rear brake pressure.