We hope that you all are keeping well in these challenging times. Like many, we’ve been using the time to get a few smaller projects done on the CR-X. Things we’ve never been happy with since the car was put together 4 years ago. Things that were rushed, or we simply didn’t know any better at the time.

The engine bay before we began, functional but very untidy:

First task was to pull out the gearbox to fit the shiny new OS Giken differential. We’ve been running this car with a standard DC5 Type R diff up to this point, we’re hoping changing to a clutch type will be worth some time. Our local track Winton has a number of corners where it’s very easy to unload the inside front at the exit, causing the inside wheel to spin up with the helical OE differential

New diff bearings, and remembering to swap the speedometer drive gear over (which we’ve forgotten before!). A quick check of the clearance from the diff bearings to the casing, a new shim, and we got it all back together.

While we’ve got the suspension apart we’ve made a small revision to our custom traction bar. When we fabricated it initially, we used a standard Aurora 5/8″ Performance Race rod ends. Since we’ve found that it’s right at the limit of its available misalignment angle with the amount of travel in our current shocks. We definitely didn’t want to be bottoming out the rod end and putting torsion loads into the radius rod they’re not designed for.

So we’ve changed to a high misalignment type rod end, which takes a 1/2″ bolt. We’ve welded some special spacers in place to correct the bolt size, and had some custom spacers made to fit the existing width of the clevis, so we didn’t have to re-make the whole thing.

Digging about further in the engine bay, we discovered this crack in the suspension sub-frame:

Check your sub-frames guys! We’ll pull out another sub-frame from our stash and modify it for header and transmission clearance like this one, as 4 years of hard use is pretty good service life. We’ll have to come up with a more permanent solution in the future.

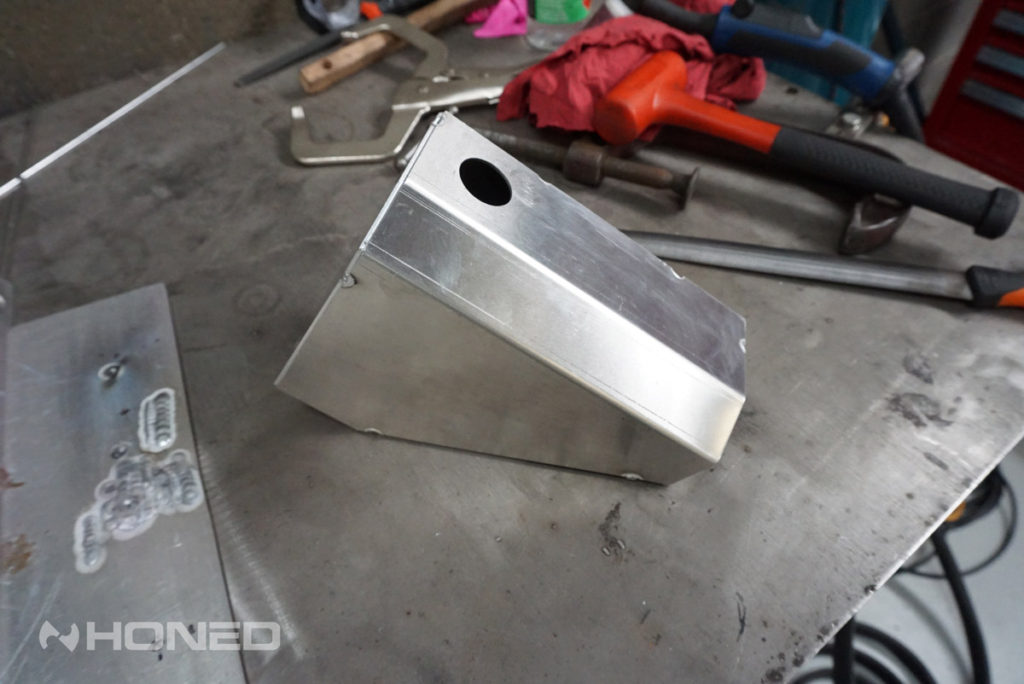

Next up, a new coolant overflow tank, to tuck it out of the way of some planned rear of engine bay activities. Some assembly required:

Taking shape:

Here’s how it will sit in the engine bay:

All finished up and mounted in place. Yes we’ll be getting it coated black, which will also hide our beginner level aluminium welding. Be assured that we get someone else to weld all our production parts!

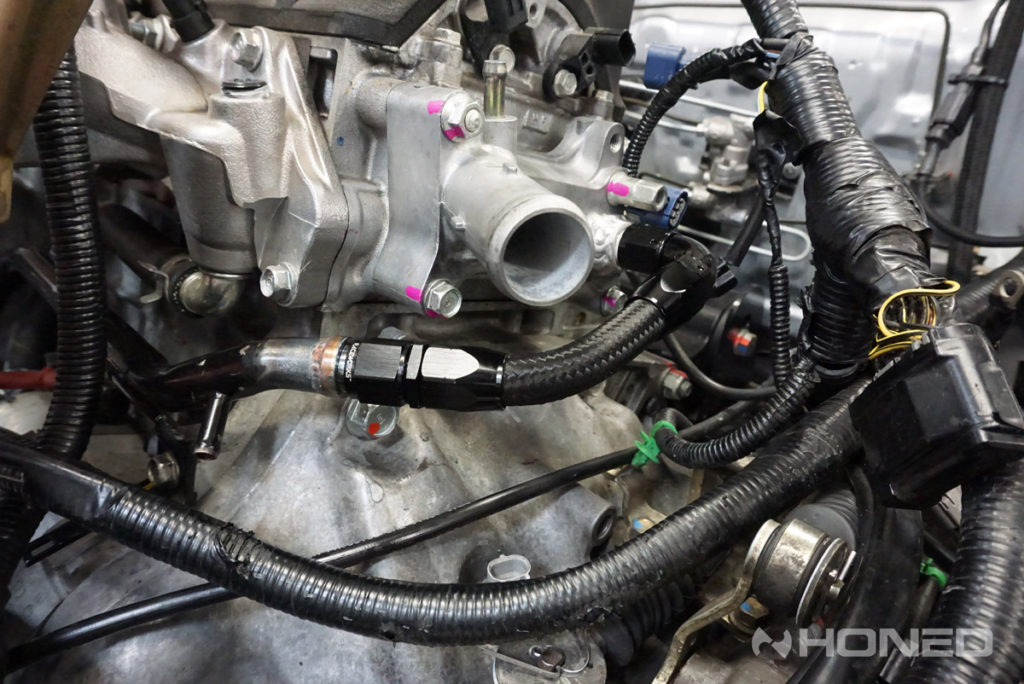

More coolant related things. We’ve removed the old loop of hose we had in place of the heater, and modified the upper coolant outlet and the tube from the coolant housing.

And finally while the gearbox is out we’ve replaced all the motor mount inserts with softer 70A in place of the 88A. For a circuit car we really don’t think the harsh 88A mounts are necessary, and we’ll be looking to better support the engine with a front engine mount to make up for any lack of stiffness in the mounts themselves:

Stay tuned for some more updates, we’ve got a bunch more new parts to make for this car.