**This post has been transferred from my long running build thread on Honda-Tech.**

I’m going to re-post the thread on this site for the benefit of the people that are not active in the forums but will still appreciate the content.

The photos might not be as good as the more recent posts but there’s still some great content

If you’re interested in the Sedan build you’ll want to read up on the DC2 as well!

A lot of the customs parts such as the tie rod ends, brake booster delete and rear trailing arm modifications were developed on this DC2 Chassis

Enjoy the read

Cheers Grant

One of the biggest draw back to the Vti-r shell is that it has a sunroof. I have read that the sunroof components weigh about 15 kg, obviously this weight is concentrated at the highest part of the car.

I’m trying to get the weight of the car down as much as possible, lowering the COG height is a big priority as well.

The weight is one issue, another is the stiffness of the roof panel. The steel bracketry that supports the sunroof probably supports the roof skin a little but it’s not ideal.

I did some research on Sunroof delete kits and failed to find anything that was simple yet didn’t look like a total hack job.

I came across a company in the US that made a carbon panel which would be perfect except you can’t actually buy them at the moment.

That company also required the installer to weld to the roof panel and fix flimsy looking brackets to hold the panel in place.

Sure you would have a carbon panel sitting there but it would do little to support the roof skin

I decided that I could come up with something better myself.

I wanted a panel that:

1) Followed the original contour of the roof

2) Was easy to install

3) Increased the stiffness of the roof panel

4) Looked tidy

I made contact with a composites expert and arranged for a plug and mold to be made. He seemed confident we could come up with a panel that could be bonded into place.

This weekend it’s all coming together so I started preparing the car

Head liner removed; I’ve had the interior of this car apart so many times now I’ve got removing the panels down to an art form. I thought removing the headlining would be a time consuming task but I was pleasantly surprised I had the whole lot out in a hour.

This is what you are left with

Here is the Sunroof panel mold receiving it’s final preparation before the carbon is laid down. We are doing a lay up tonight and if it comes out alright we will be bonding it into the roof tomorrow.

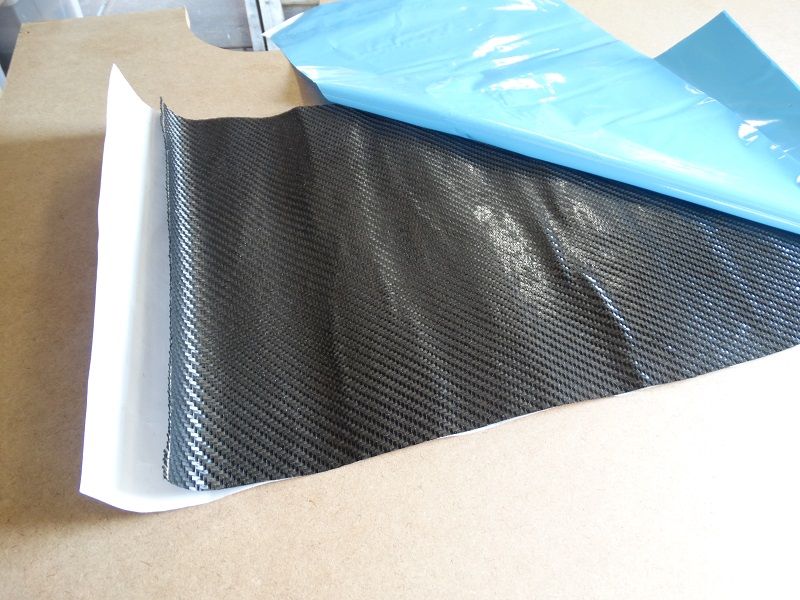

The material we are using is from Advanced composites, it’s prepreg material; 200g/sm, 3k, 2×2 twill for those carbon aficionados

Although the sunroof install was planned for last Sunday the weather in Melbourne took a turn for the worst delaying our progress, however the panel is now installed

and I couldn’t be happier with the result!

Once the headlining is out, the sunroof can be removed easily

This is what you remove, the sunroof assembly including the motor and rails weighs around 15kg so removing it gives a significant weight saving.

Then we masked the roof around the sunroof cavity

Next step was to sand the return on the roof back to bare metal. This gives the adhesive a good surface to bond to

Now we drop the new carbon panel into place, we used large clamps to hold the panel securely

I re-installed the sheetmetal base of the sunroof and used that as a ledge to shim the panel level with the roof

Once the panel was sitting correct we used sikaflex to bond it to the roof. We kept the clamps in place until the sikaflex cured to full strength.

The finished result

Even just driving the car around the streets the improvement in chassis stiffness is noticeable! The feel of the car has improved and this modification has affirmed my love for the Dc2 chassis.

It seems that with every kg that I remove I’m rewarded with improved feel and better response to driver inputs.