Here’s a run down on the work that I’ve been doing on the Sedan in the past few weeks

I re-installed the motor and gearbox so that I could check my driveshaft angles and work out the routing for the fuel line and engine oil cooler

I have a Turbosmart FPR and a Aeromotive inline filter and I intend to plumb the fuel line with -6an fittings and black nylon covered hose

This is what the drive shaft angle looks like with the engine mounted in the standard position and the wheel hub ~250mm from the guard.

I cycled the suspension another 40mm up from here, checking that the driveshaft still rotated freely by turning it by hand every 10mm

To my surprise it didn’t seem to bind however i think i’ll relocate the engine upward by 15mm just to be safe.

Here’s a shot of my mock up front knuckle and upper control arm. Note that my outboard suspension pick up points have been relocated by 50mm compared to a standard Honda and this is the only case when the steering arm needs to be mounted below the arm of the knuckle.

Super accurate visualization of my plans for the RHS engine mount

And the same for the left. This engine mount will interact with the tubs so i’ll do the tubs first and then work out what the engine mount should look like

Speaking of tubs! I have received 4 off 28″ x 10″ mild steel trailer guards which look like so:

I probably should have realised this earlier but the fuel tank filler tube is going to be in the way of my rear tyre when it tries to move up

I don’t want to go all out with a fuel cell at this stage so my current thought is to relocate the filler to the boot somehow.

The trailing arms have been fitted with PCI’s new spherical trailing arm bearing kit. I will pull the arms out next week and repaint them

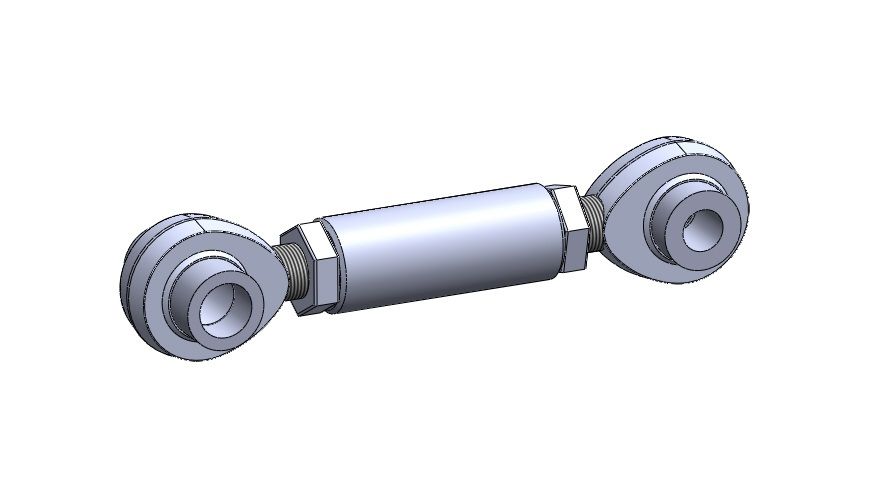

I will need custom (shorter) toe compensation arms to work with the modified trailing arms. With any luck they will look like this:

I will still be able to use the factory rear sway bar at the rear which is nice

On Sunday Tom and I assembled special tool no. 293 (a fixture for holding a steering knuckle to the bed of a drill press) and then proceeded to drill out the taper in my knuckles

The knuckle was drilled out to 15.5mm and I will then reamed the holes to a 16mm H7 tolerance which will give me a nice press fit for my shouldered inserts

The inside face of the knuckle was ground down to give me every last bit of clearance for the “wrap around” style upper control arm