The idea with this sedan is to re-create the look of the 1994 JTCC civics

In the picture I posted above of my EH, its front ride height is about 310-315mm (guard to wheel centre) and the rear is 295 -300mm

I’ve spent hours looking at pictures of the JACCS cars and other EG9s from JTCC and by best guess is that ride height of those cars is somewhere in the 255-270mm range

Now I know from my suspension modeling that the standard suspension geometry can’t achieve that kind of ride height and maintain anything close to stock camber gain/toe curve/bumptravel etc

I also know that i’ll be physically limited by the tyre contacting the inner wheel arch so undoubtedly there will have to be some modifications to the sheetmetal

I plan to design and have manufactured a pair of front knuckles for the car

The trailing arm suspension will be replaced with a new design too

The new knuckle will be designed to re-position the wheel hub approximately 40mm up from stock

At this stage i’m thinking i’ll reuse the forged lower control arm but instead of staying with the high upper ball joint design i’ll try and package a s2000 upper control arm inside the wheel

I’m currently looking into bolt on hubs to suit RWD or AWD vehicles that might have the same bearing dimensions or same spline as the Honda front hubs/wheel bearings

If i can find something that matches the honda stuff it should reduce the amount of work required for the knuckles

I like the look of these fabricated knuckles, they are designed to receive a bolt on hub of some description

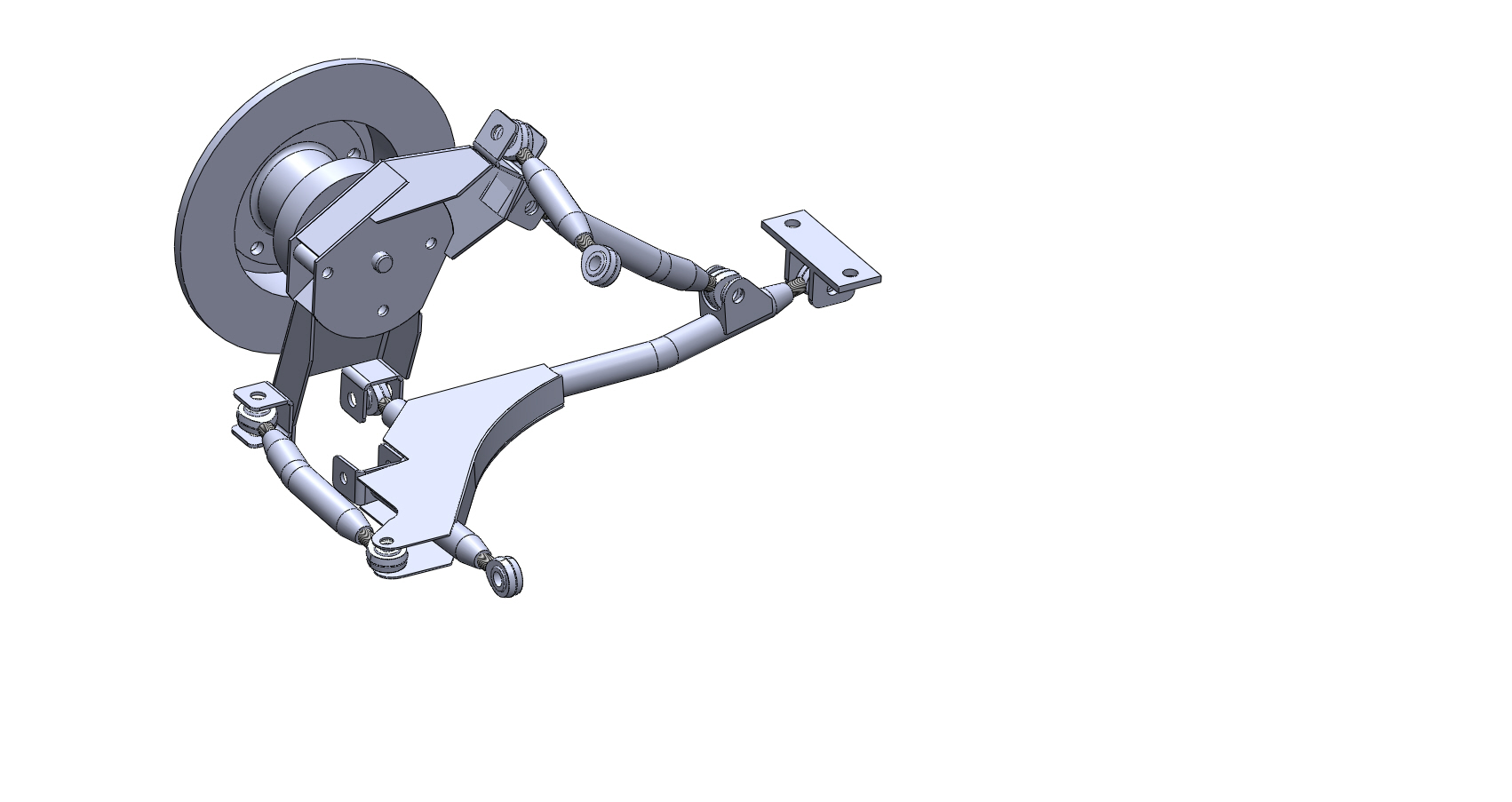

I’m already into the rear suspension design

It’s early days and the CAD model is still very rough but you can see the general shape of the idea

The rear suspension design is inspired by this photo I found on the super tourer register website

Its of the rear suspension from a Honda accord super tourer

Now without a doubt all of this is going to be costly and time consuming but its not quite as bad as it seems

I already own all the rod ends I need for the rear suspension and that was a major factor in swaying my decision to go whole hog with this thing

When I dismantled my sports car project I boxed up all the suspension links and rod ends and brought them to Australia with me and so now i have boxes of QA1 1/2 UNF rod ends..

The rod ends are not the only thing i want to re-use from the sports car project

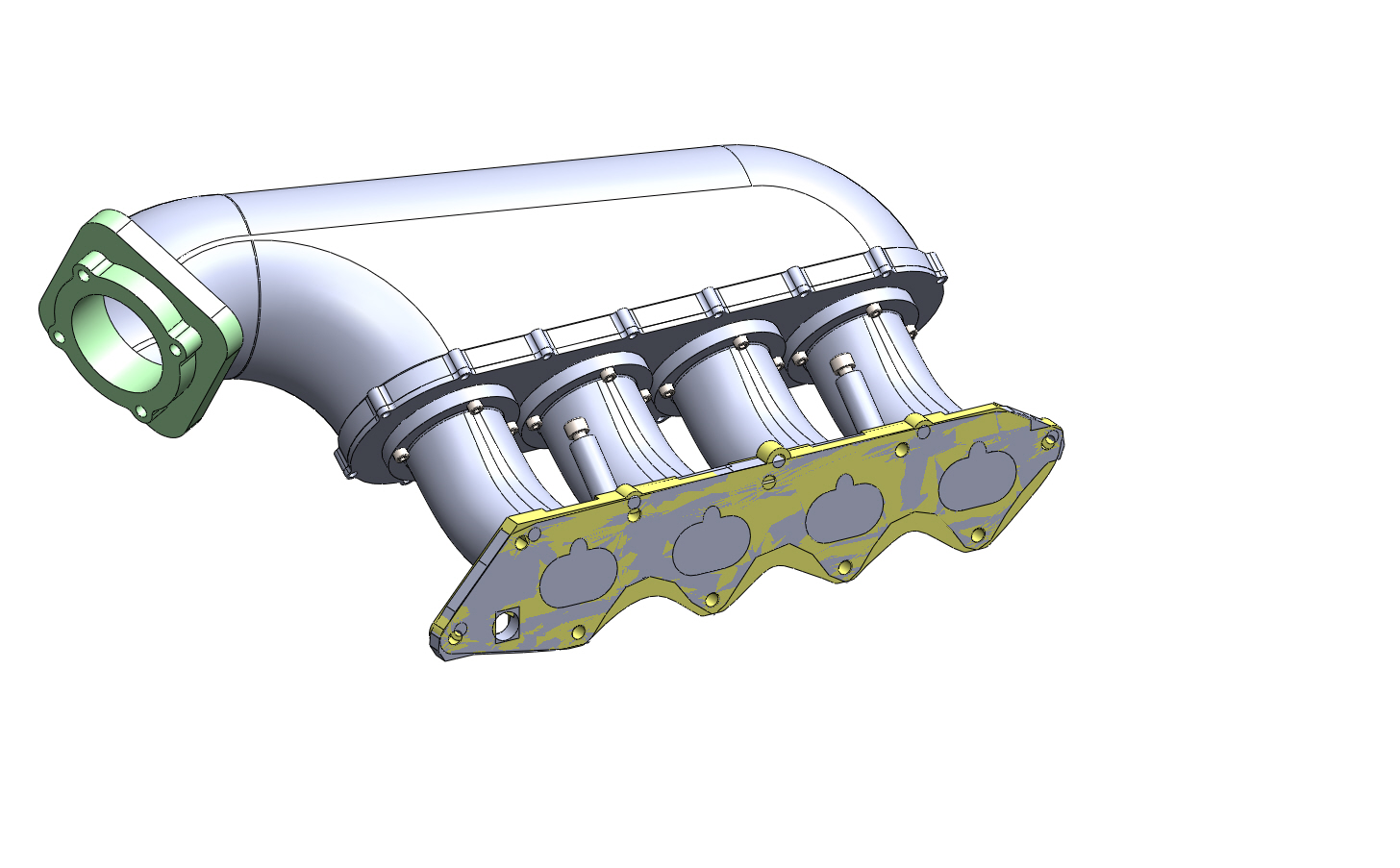

I also have the custom intake manifold that was designed and manufactured for the sports car by my friend Martyn

This is such a cool piece a total one off, I’ll take some good photos of it as i get it finished off

I realise it’s kind of a waste to put this on a stock b18c2, I want to use it just for its sentimental value

The original flange for this intake was made to suit the b16a so to use it on my b18c2 I have to get a new flange machined (yellow)

I’m part way through re-modelling the flange

On Sunday I went a local pick-a-part and procured a VZ commodore e-throttle and accelerator pedal

The throttle body ID is 70mm

In this photo i’ve got the throttle body bolted down on the CMM table

I used the CMM to measure the mounting flange of the TB and from this i’ll get a mounting plate machined up to adapt the TB to the manifold plenum

[irp posts=”1131″ name=”JTCC Inspired Civic Sedan Build 3: Intake Flange”]