Honda’s L15 engine hasn’t been a popular choice for modification here in Australia, but with the cost and availability of B- and K-Series engines increasing and decreasing respectively, we decided to take a closer look at the potential of the humble L-Series.

However, not all L15s were created equal, so in this article we’ll break down the differences between the early L15a1 and later L15a7 engines, tell you which has greater modification potential and which modifications are the best ones to make.

Honda L15a1

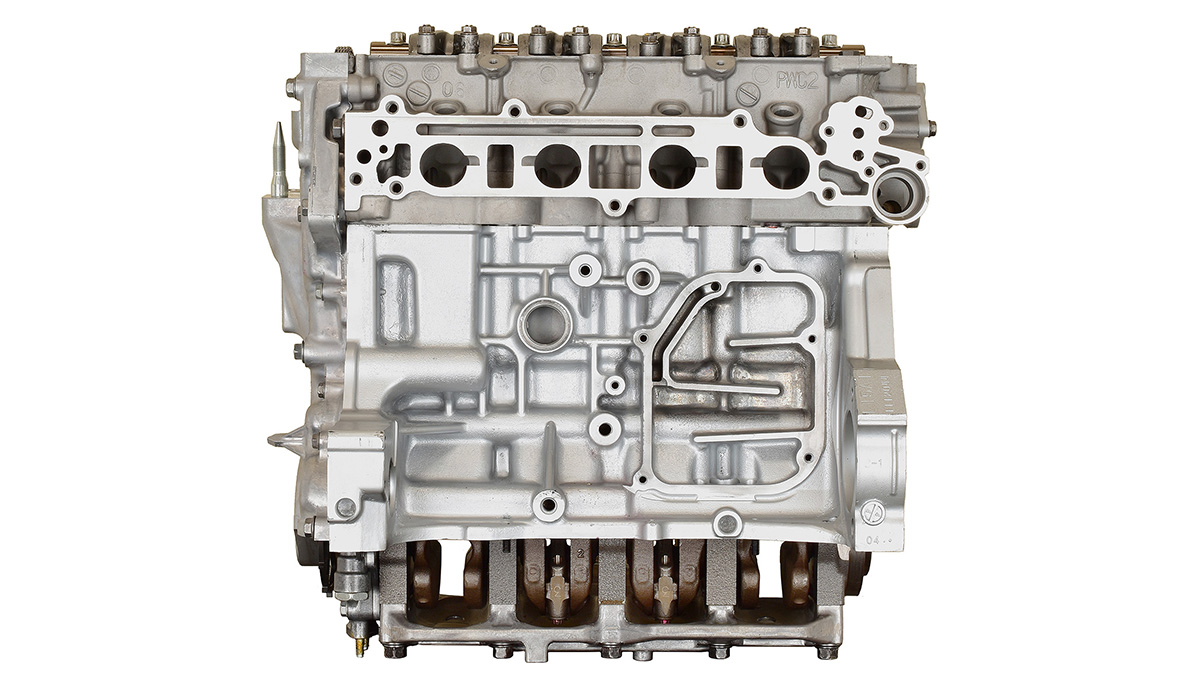

The L15a1 was the primary global engine in the first-generation (GD) Honda Fit/Jazz. Heavily undersquare, a 73mm bore and 89.4mm stroke result in a 1497cc capacity and the compression ratio is 10.4:1.

In stock guise, Honda quoted engine figures of 82kW at 5800rpm and 143Nm at 4000rpm, which on Australian dynos typically equates to around 55kW at the front wheels.

The L15a1 has some very unique features for an economy car engine, including a timing chain to transfer drive, roller rockers to reduce friction in the valvetrain and its single overhead-cam configuration makes it very compact.

Where things get slightly confusing is Honda’s application of the VTEC designation, which is typically associated with multiple cam profiles for improved high-rpm performance.

In the L15a1, a split-rocker system allows the engine to operate with one or both intake valves per cylinder depending on load. Well, the second one does still open, but only a fraction to prevent fuel pooling.

At low rpm, this 12-valve operation results in a leaner mixture to improve fuel economy, with all 16 valves opening at medium-to-high rpm to ensure an appropriate air-fuel mixture.

Other features of the L15a1 are a mechanical throttle body, four separate exhaust ports and the fact the camshaft comes out of the head sideways rather than through the top. Despite this, camshaft removal and installation can be completed with the engine in the car.

Honda L15a7

For the second-generation (GE) Honda Fit/Jazz, the L15a7 engine was introduced. On paper, it looks very similar to the a1: same 1497cc capacity, same bore and stroke, same compression ratio.

Engine outputs improved to 88kW at 6600rpm and 145Nm at 4300rpm and that peak power figure – or, more accurately, where that power is produced – is the first clue that there are some important differences between the two engines.

In our experience, the a7 typically produces around 58kW at the front wheels, a three kiloWatt gain over the a1, with the GE’s power curve separating from the GD’s beyond 4200rpm.

Unlike the a1, the a7 does have variable camshaft profiles – VTEC in the traditional sense – though only on the intake side. On the exhaust side, there are no longer individual ports, the four cylinders instead converging into a common port within the cylinder head.

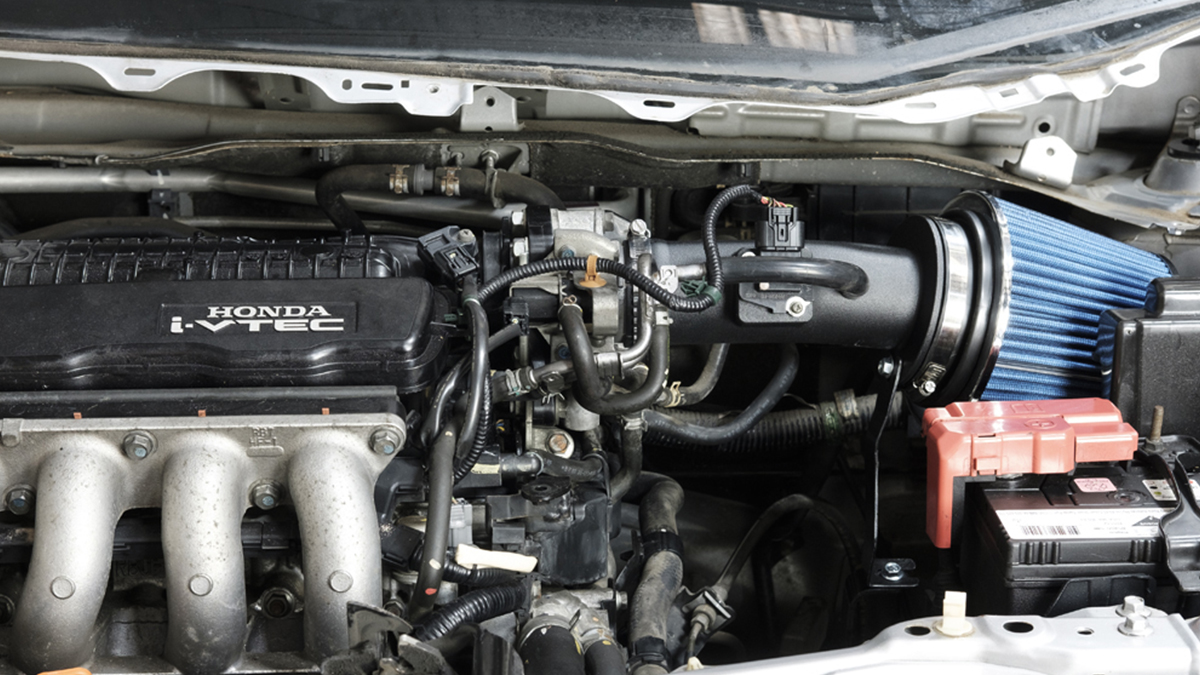

Another important feature to note is that in addition to a manifold air pressure (MAP) sensor, the a7 also has a mass airflow sensor (MAF), which has repercussions if you modify the intake system.

How to modify the L15 engine

Being a small-capacity, naturally aspirated engine, the only way to get the L15 engine to make substantially more power is to rev it harder. Nevertheless, there are still gains to be made with basic modifications.

Before we get to that, one easy way to clean up the engine bay of your GD Fit/Jazz is with Honed’s VTEC and exhaust gas recirculation (EGR) deletes. Given the ‘VTEC’ system on the L15a1 just shuts off an intake valve at low rpm for greater fuel efficiency, in a performance application we don’t need that.

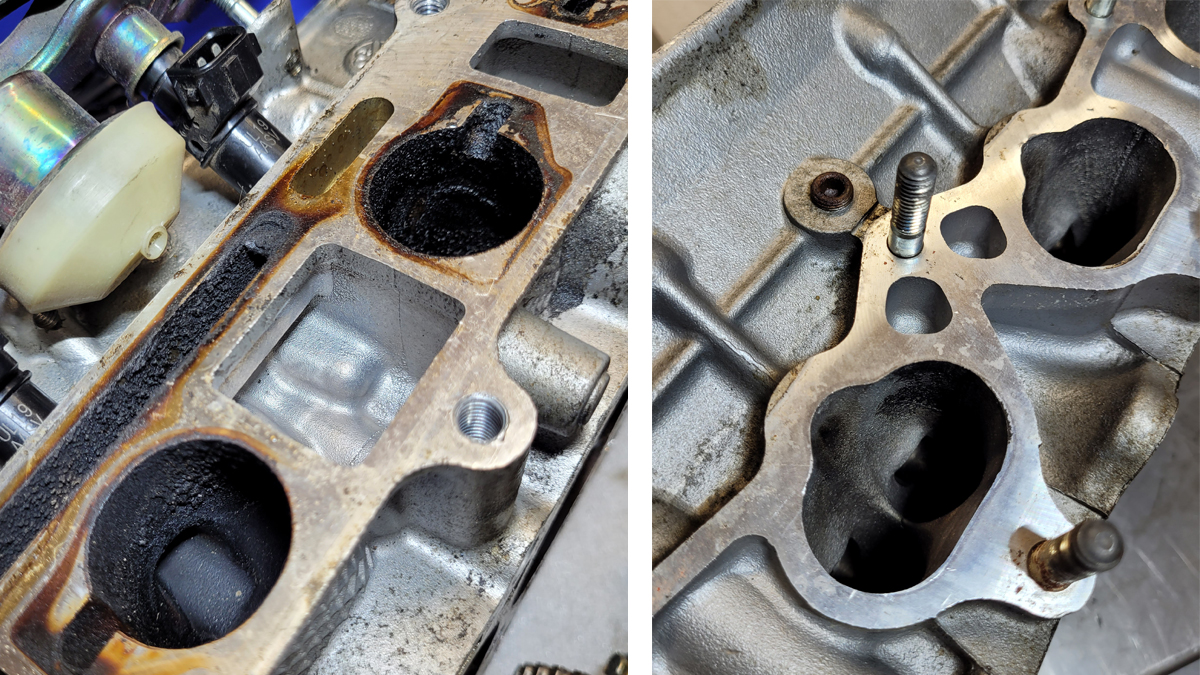

The EGR delete not only liberates more space in the engine bay and saves some weight, but it prevents pre-burnt exhaust gasses from being fed back into the cylinders. This can result in carbon build-up as the image below illustrates, comparing an L15 with EGR on the left to a non-EGR D16 on the right.

Note that these products are intended for modified engines with aftermarket engine management systems.

To illustrate the difference each modification stage makes, we’ll use the L15a7 in Honed’s GE8 project car as an example.

The easiest way to extract more power is to optimise the car for 98 RON fuel. From a baseline of 54.6kW at the front wheels, a CMS Performance tune on the higher-octane fuel increased this to 60.7kW atw, an impressive 11 per cent gain.

The next step for the L15a7 was to install a performance camshaft, uprated valve springs to cope with the higher rpm and a 2.25-inch exhaust.

While the standard engine has a rev limit of 7000rpm, peak power is produced at around 6250rpm and raising the rev limit with the 98 RON tune paid no dividends, power continuing to trail off from the peak.

With the new top end modifications, the rev limit was raised to 8000rpm and the new camshaft increased power substantially from 5500rpm onwards, with a new peak of 75.4kW atw at 7500rpm.

There was a slight reduction in power below 3500rpm, but this was more than compensated for by the increase at high rpm, especially in a performance application.

In terms of intake modifications, the a1 engine is easier as its lack of MAF means anything ahead of the throttle body can be changed freely, whereas the a7 needs to have an intake that’s matched to the MAF.

There are gains to be made over the standard intake, however, Honed’s 57mm intake resulting in a 3.6kW atw gain compared to the OE airbox for a total of 79kW atw, a massive 45 per cent increase over standard.

Also of interest is that further experimentation with a larger 76mm intake resulted in only fractional gains of less than half-a-kiloWatt.

At this point we were limited by knock on 98 RON fuel. Subsequent runs on 102 RON fuel only resulted in a small gain of 2.1kW at the front wheels (now 81.2kW atw) but gave the engine a safety margin under full load.

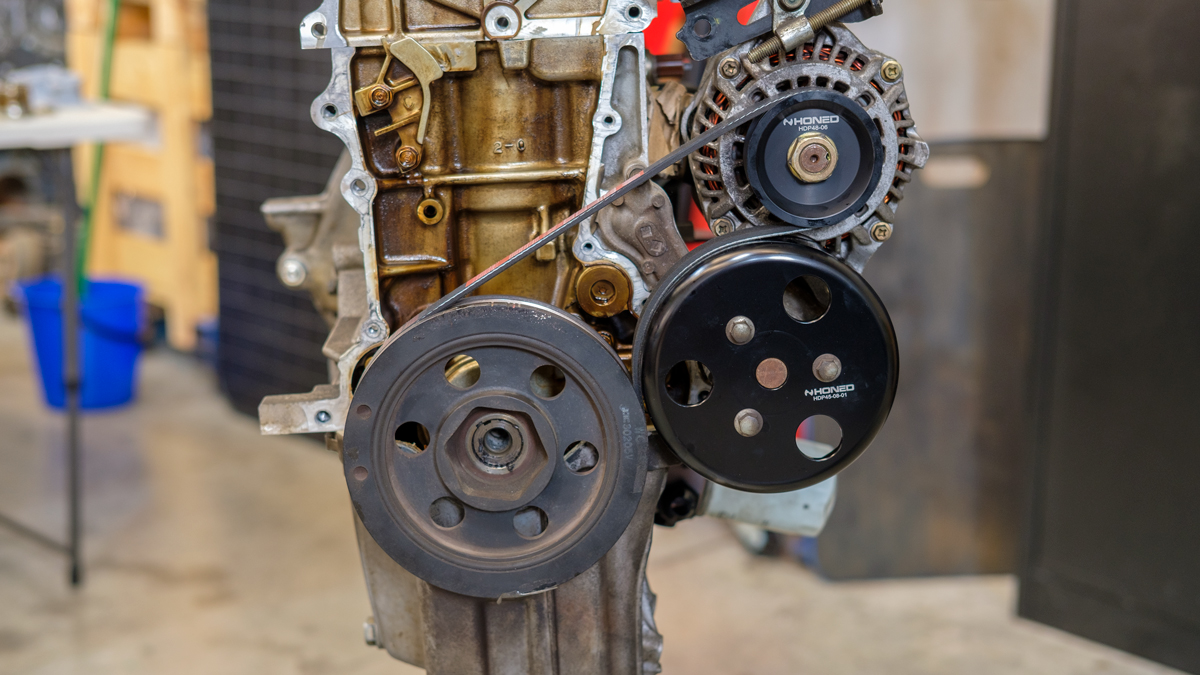

An important consideration when revving a non-performance engine like the L15 higher is the stress it will put on associated accessories. Spinning the engine almost 15 per cent harder (8000rpm vs 7000rpm) may lead to failure as these accessories are stretched beyond their intended operating window.

To compensate for this, Honed developed underdrive pulleys for the L15a1 alternator (4.5 per cent larger, 71g lighter) and both engine’s water pumps (nine per cent larger, 255g lighter) to keep them operating at OEM speeds.

Another important consideration when driving an L15 in a high-performance environment, especially with improved suspension and grippier tyres, is ensuring a consistent oil supply. The Honed sump baffles for the a1 and a7 create an enclosed volume around the oil pickup even under high g-force loadings.

Is the L15a1 or L15a7 better?

As you might expect, in base form the newer L15a7 is a superior engine and possibly has higher potential. While its converged exhaust port is theoretically inferior in a performance application, Honed’s GE8 has shown it not to be a handicap.

However, the L15a1 has advantages with its simpler intake system, and if a replacement camshaft is going to be installed, the newer engine’s VTEC system is of marginal benefit.

In summary, while the L15 isn’t the obvious choice when it comes to creating a performance Honda, there is nevertheless plenty of potential to be extracted with the right modifications.

How To Improve Honda Crankcase Ventilation

A walk through of the issue of crankcase ventilation and what we recommend to do about it

Improving Honda Fit/Jazz (GD3) Driver Ergonomics

All the modifications we’ve made to the driving position of the Honda Fit/Jazz to turn transform it from economy car to track star

Honda Fit/Jazz (GD3) Suspension Recipe

The ideal suspension setup for the first-generation Honda Fit