THE CASE AGAINST DUCTED HOSE

- Inlet ducts, the hosing, backing plates, mounting brackets and more all have to be bought or made which increases cost.

- A flexible duct set up requires a backing plate or caliper mounting bracket with an integrated duct, which ends up being caliper-specific due to packaging.

- The wheel hubs have to be removed to change the rotor backing plates, which usually requires new wheel bearings, further increasing cost.

- An inlet duct has to be incorporated into the front bumper which is a permanent modification.

- Flexible tubing is difficult to fit in the wheel arch without interfering with the driveshafts or the wheels steering.

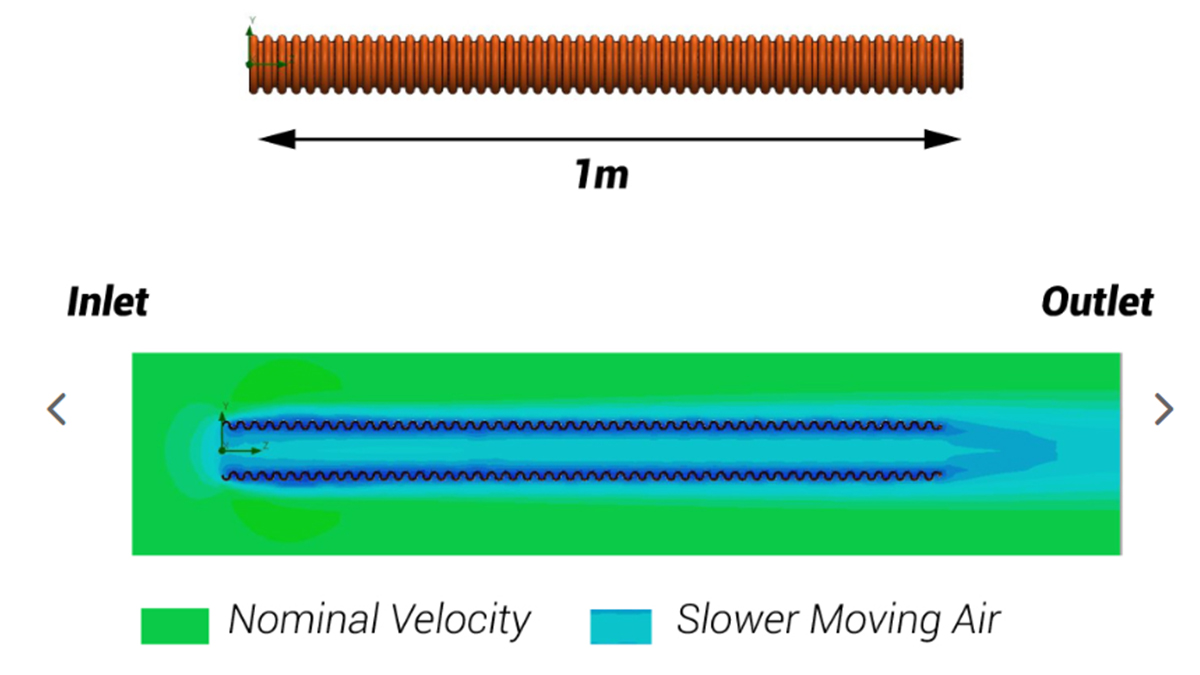

CORRUGATED TUBE AIRFLOW IS TERRIBLE

Air speed at the outlet of the flexible corrugated tube could be HALF the inlet speed due to the high internal air flow resistance. And this is the case when it’s straight, let alone when bends enter the equation…

AIR GUIDES ARE AN OEM SOLUTION

Air guides are favoured by the world’s leading performance car manufacturers, including the Porsche 911 GT-series and Chevrolet Corvettes.

The Honed Developments brake cooling air guides (Honda S2000 LHS shown) have proven to have the following benefits:

- 20 per cent disc temperature reduction

- Reduced pad fade

- Longer pad life

- No bodywork modifications required