Earlier in the year we tested our air guide kit on the D15 powered Civic and gathered some interesting data, this time out we’re testing to see how aero modifications affect the air guide performance. Our CR-X is a perfect example of common track day car aerodynamic upgrades, along with the big wing it’s fitted with an air dam and splitter extending back well under the car. With the splitter blade only 70mm (2.75″) off the ground we’d expect less air flow under the car compared to stock bodywork on our EF Civic, so we wanted to see how this affected the brake cooling.

The test process was simple; we rigged up thermocouples on both the front brake discs to record the disc temperature in real time. We ran some sessions with the air guides in place, then with the air guides removed for comparison. The test circuit was Winton; mostly low speed corners with some fairly long braking zones. The brake system on the CR-X is very basic: Stock 262mm discs with some braided brake hoses, with Hawk DTC60 and DTC30 pads at the front and rear. The air guide kit is fitted with the lower edge at our recommended height of 75mm from the ground.

Tagging along to the same test and tuned day were the guys from Python Racing in their very serious Cobra race car. We’ve been providing chassis setup advice for the team as they compete in a local sports car race series:

This car runs a Nascar derived Ford V-8, so it has plenty of straight line speed, but the handling needs some development. We designed a set of bespoke set of upper and lower front control arms to improve some issues. The arms relocated the roll centre, corrected the scrub radius and modified the steering geometry to provide much improved front end feel and grip, much like the bumpsteer and roll centre products we offer. Like any car, it’s important to start with a base of solid suspension geometry before chasing setup with spring, shock and other changes.

We ran a bunch of laps through the day, more than 40 by the time we packed it up and headed home. Now on to the data.

Data Analysis

The graphs below summarise what we discovered from the data. Firstly there is some inherent variance between the left and right disc temperature values, simply due to mounting of the sensors and other unpredictable effects. So to allow accurate comparisons we’ve corrected the data for this variance by comparing the individual brake disc temperature to the average of both discs. So a value of 40°C means the disc temperature was 40° above the average across both discs.

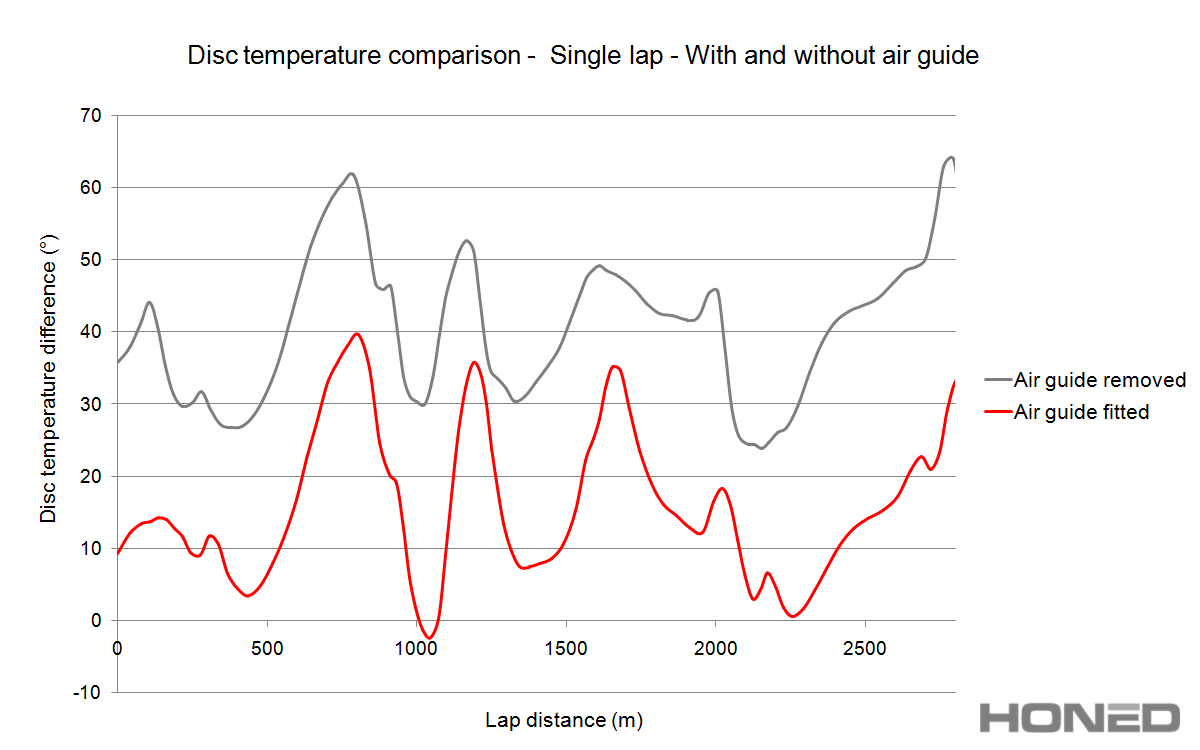

The graph below shows these values for the last lap of 2 consecutive sessions, with both laps the fastest of their respective sessions, in the high 1:32s range. The temperature with the air guide in place is consistently 20-40° lower throughout the whole lap, a reduction of between 5 to 10%.

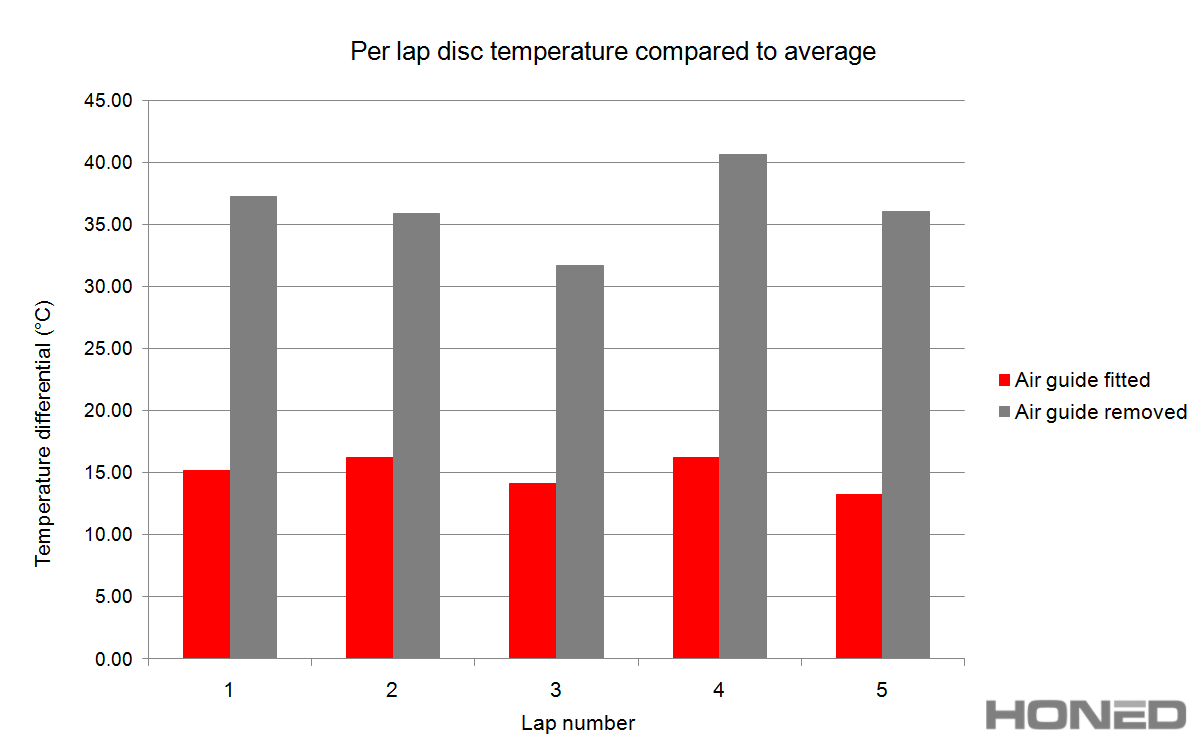

The chart below demonstrates how the disc temperature varies across a series of laps of each session. Without the air guide in place the disc is consistently 20° to 30° hotter on average each lap, an increase of 4.5 to 7%.

The chart below demonstrates how the disc temperature varies across a series of laps of each session. Without the air guide in place the disc is consistently 20° to 30° hotter on average each lap, an increase of 4.5 to 7%.

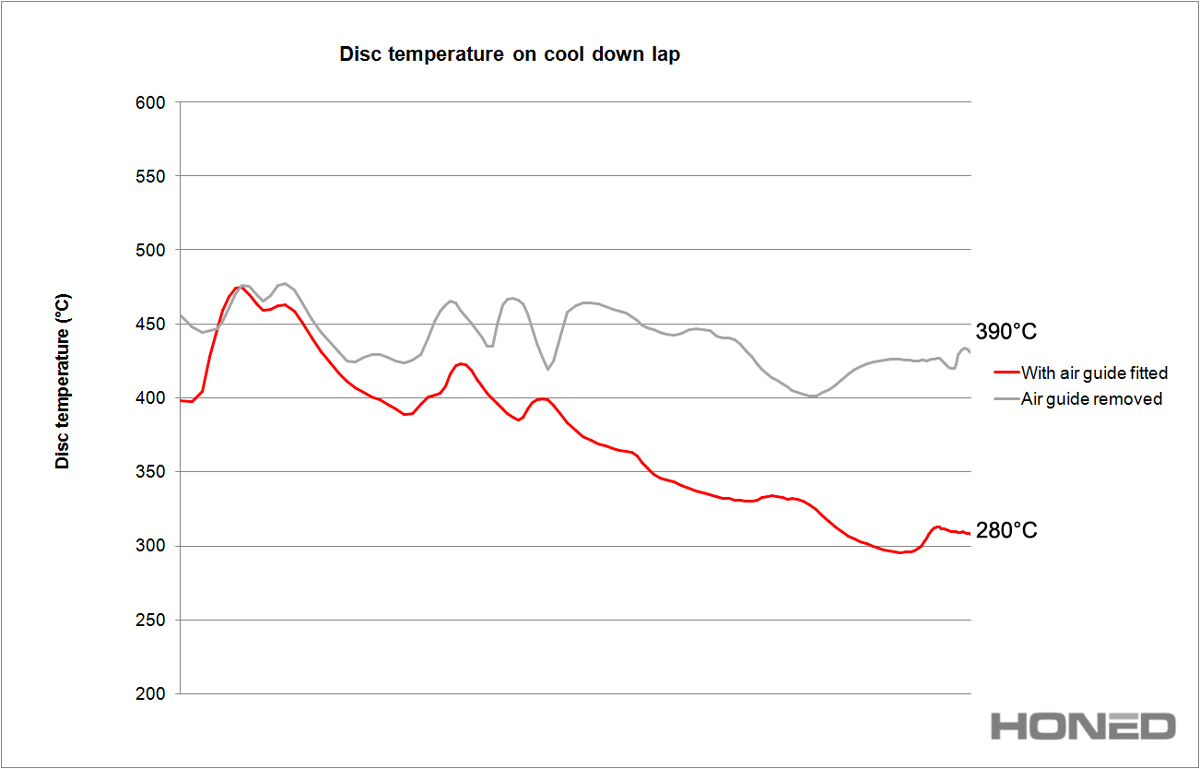

The graph below shows the temperature of the front left disc, with and without the air guide in place, on a cool down lap before entering the pits. The cooling effect of the air guide can be seen clearly with the extra air flow bringing the disc surface temperature down much more quickly. With the the air guide fitted the temperature of the disc is reduced a full 90°, despite starting the lap with near identical temperature.

The graph below shows the temperature of the front left disc, with and without the air guide in place, on a cool down lap before entering the pits. The cooling effect of the air guide can be seen clearly with the extra air flow bringing the disc surface temperature down much more quickly. With the the air guide fitted the temperature of the disc is reduced a full 90°, despite starting the lap with near identical temperature.

It’s clear from the data that even with a splitter in place the air guides produce effective brake cooling, performing nearly as well as our earlier testing with the stock bodywork EF Civic. We also managed a new PB on the Rival S at this test day with a 1:32.4, but we’ve since gone faster again, so we’ll cover our PB progress in a further update on our recent track events soon!