**This post has been transferred from my long running build thread on Honda-Tech.**

I’m going to re-post the thread on this site for the benefit of the people that are not active in the forums but will still appreciate the content.

The photos might not be as good as the more recent posts but there’s still some great content

If you’re interested in the Sedan build you’ll want to read up on the DC2 as well!

A lot of the customs parts such as the tie rod ends, brake booster delete and rear trailing arm modifications were developed on this DC2 Chassis

Enjoy the read

Cheers Grant

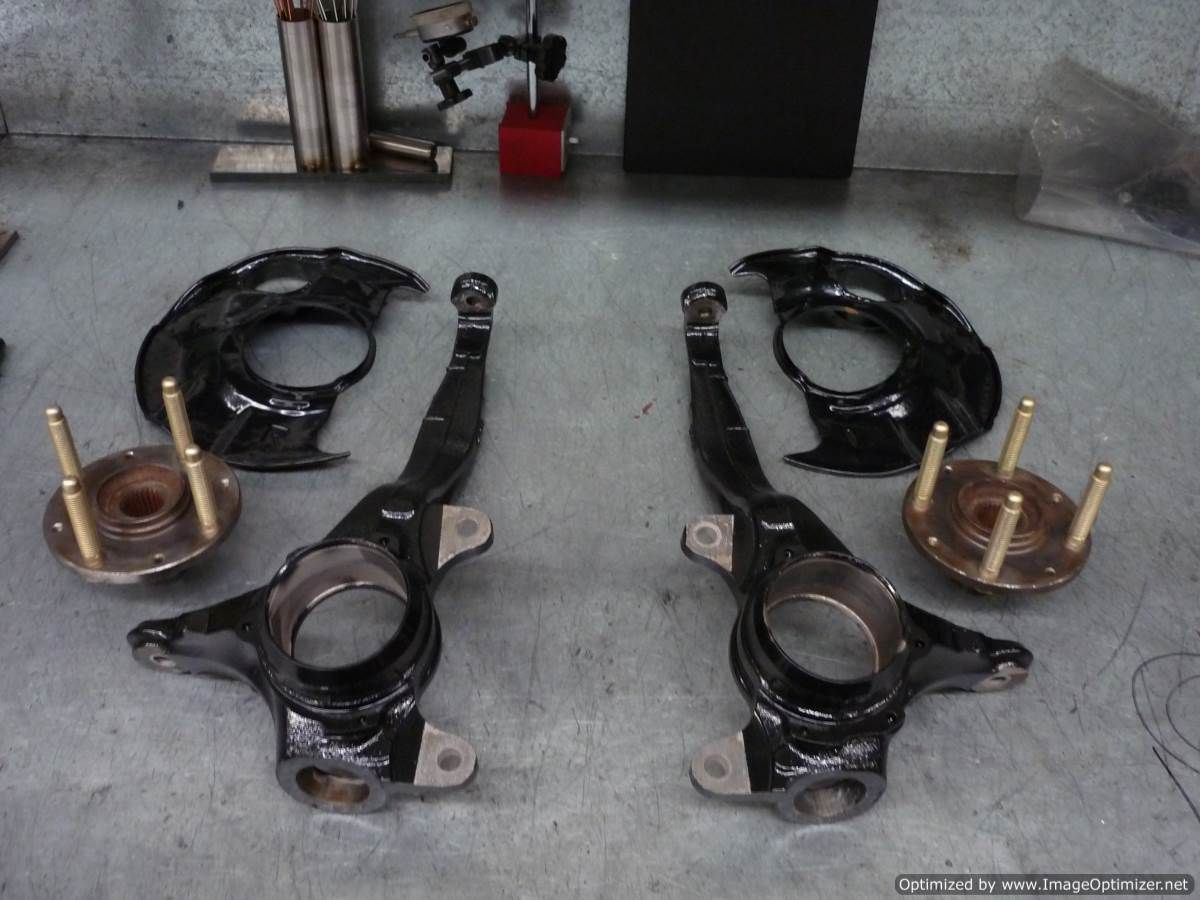

I did a bit of wheeling and dealing and got myself a set of dc2 uprights to rebuild. It wasn’t until I got home from the seller’s place that I noticed the uprights were from a non-abs GSI model dc2. Dam!

I did a bit of research and found the ABS system in the early Dc2’s is basic enough that I won’t compromise the braking performance of the car by removing it.

Removing the ABS will give me part of the weight reduction over the front axle i’m looking for.

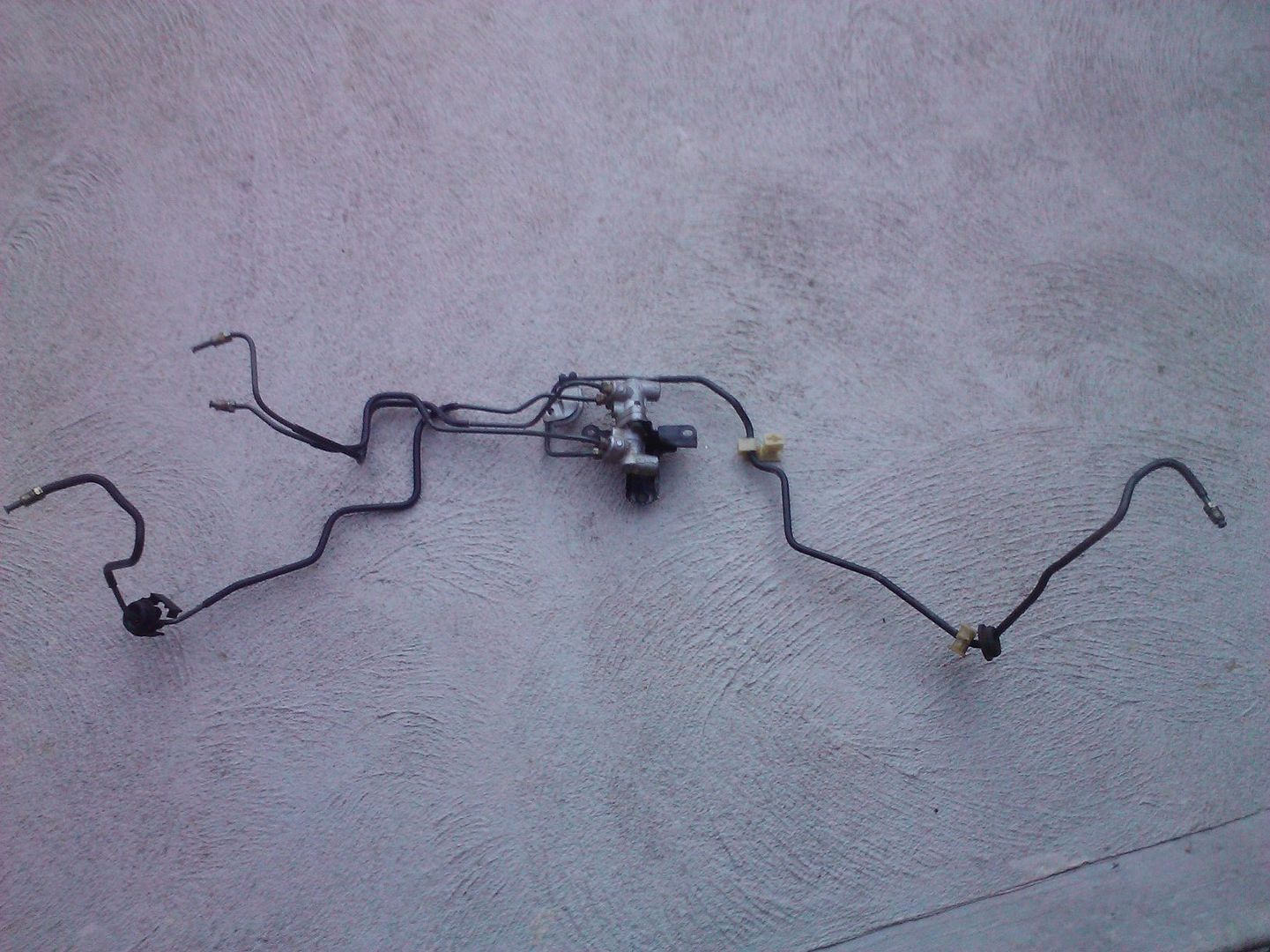

I called the seller up and sure enough he still had the complete set of hardlines from the GSI including the 40/40 bias valve. I convinced him to throw in the hardlines as otherwise the uprights were no good to me.

I spent Sunday converting the car to non Abs. It was difficult to access all the lines with the engine in place and I was very grateful to be working with the car on a hoist.

I removed the original front hardlines, abs pump etc in a couple of hours, then once I had most of the new lines in place I discovered the GSI hard line that connects to the brake master cylinder had a different size fitting on it. I did read a few ABS removal guides that mentioned this but for some reason I thought it might have been a USDM issue only.

I gave ChargeR a call and he came around with an old tube flaring tool. The flaring tool was well past it’s prime and we ended up needing an assortment of extras to get it to work. These included washers, welding wire, cable ties and a big crescent.

Once that mini drama was sorted out it was plain sailing. I checked all the fittings and paint marked them for quick reference in the future.

We bled the brakes through with ATE Super Blue racing brake fluid that I sourced a few weeks ago from Autosphere (thanks Mugsee)

If you recall I reported my brakes feeling soft and lacking in bite power after the Winton track day. I have another set of front brake pads of unkown origin but visually good condition and decided to swap them in, to replace the ones that were on the car when I did the track day.

I was quite surprised at just how bad the pads that came out were. All the pads were cracked in the middle and most had large chunks missing. I guess this is what happens when you ask a pad to operate out of its design temperature range.

The leading edge of the pads had just disintegrated

I have decided to go to a 2 pad/rotor set up. I will get a set of race pads and rotors before the next event.

In other news the knuckles and rotor shields are at the power coaters, i should be picking those up tomorrow.

The extended studs arrived today. I also have a complete set of stainless clamps for the axle shaft CV boots, I plan to rebuild the cv’s with redline CV2 grease.

The uprights are back from powder coating, like the RTAs, they look a million bucks. If you’re rebuilding your suspension it’s well worth the time to get parts powdercoated vs bombing them with a rattle can.

I pressed ARP extended wheel studs into the hubs as I plan to run small wheel spacers on the front in the future.

There’s been a hold up with the Mfactory parts and it’s looking like another 2 week delay until I get the new suspension set up installed. Bummer.

Today I stripped the sound deadening out of the car. I didn’t take any great pictures but I’m sure you all know what went down. The box of sound deadening weighed 18kgs once I was finished, so a decent weight saving!

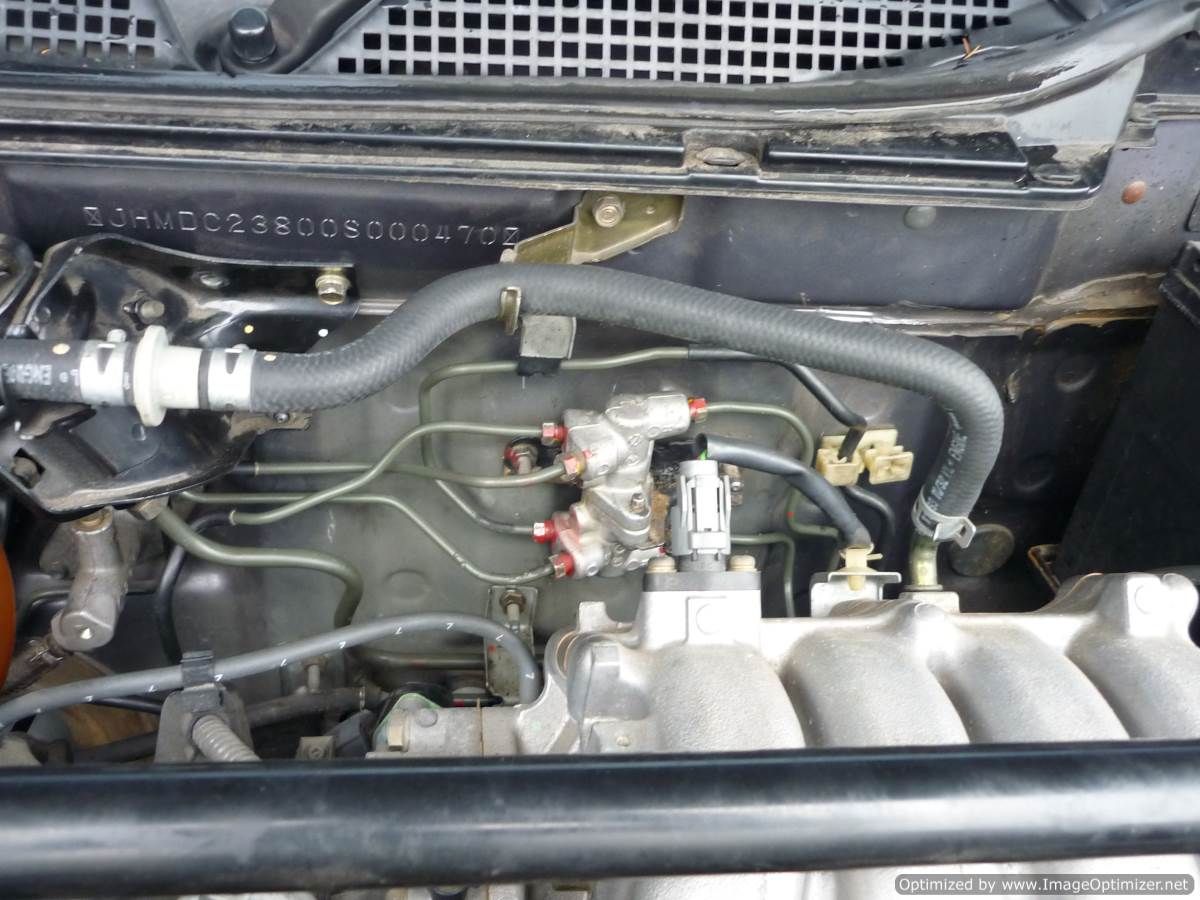

Here’s a recent shot of the engine bay, you can see the air box in place with it’s heat reflective tape.

Here’s a close up of the 40/40 bias valve. I’m loving the feel of the brakes with the ABS system removed. The pedal feel is better and the car brakes nice and straight.

Today I swapped out my fuel pump for a Walbro unit.

When i first got the car it had fuel surge issues, I replace the fuel pump with a cheap no brand replacement from Repco.

Recently I have been having issues with the pump cutting out and preventing the car from starting. This gets really old really quick!

I was glad to see the Walbro came with an insulating sleeve to prevent vibrations and cut down on some of the noise transmitted to the cabin.

Cheap fuel pumps have plastic fins

Good fuel pumps have steel gears