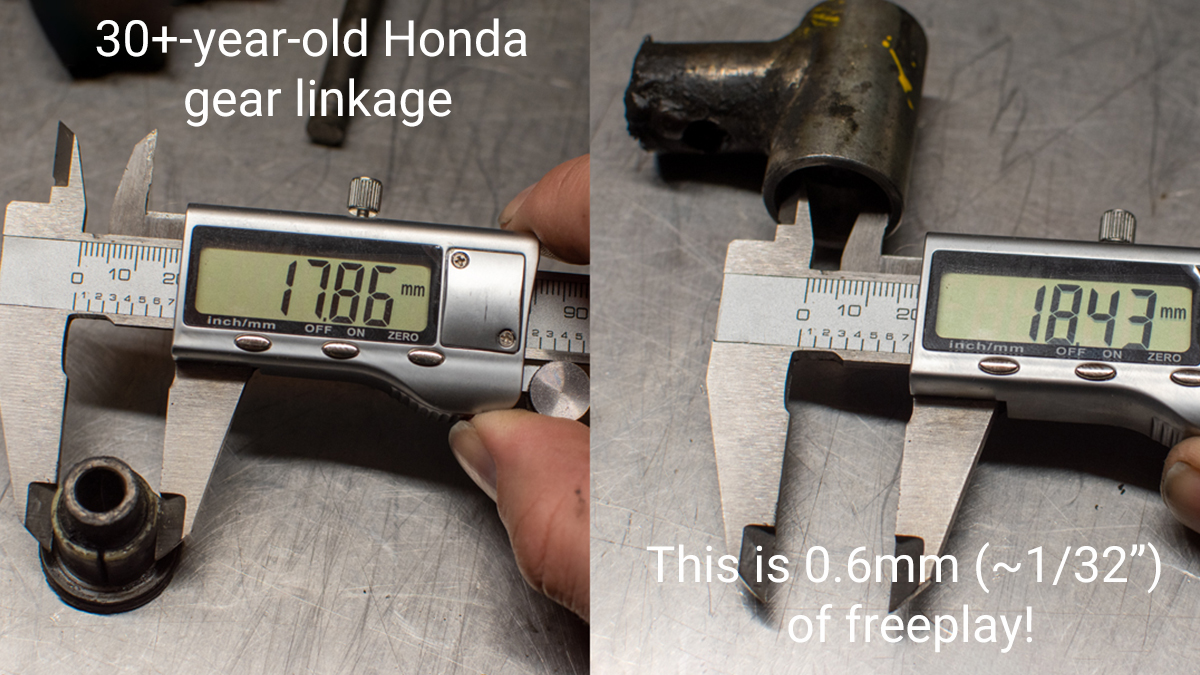

Some parts wear to the point of failure, whereas others will continue to work in a diminished capacity. One example of this is Honda gear linkages, which over time will develop freeplay resulting in reduced shift accuracy.

Part of the problem is the non-serviceable nature of the OE universal joint prior to the linkage, so when we removed the gearbox from Honed’s AH track car and found the joint completely flogged out, that was the catalyst we needed to design our own version.

Not only this, but the gearbox attachment is not designed to be easily disconnected. To solve both these problems and eliminate the freeplay that can build up as a result of worn componentry, Honed developed its own Gear Linkage Kit for Honda D- and B-Series vehicles.

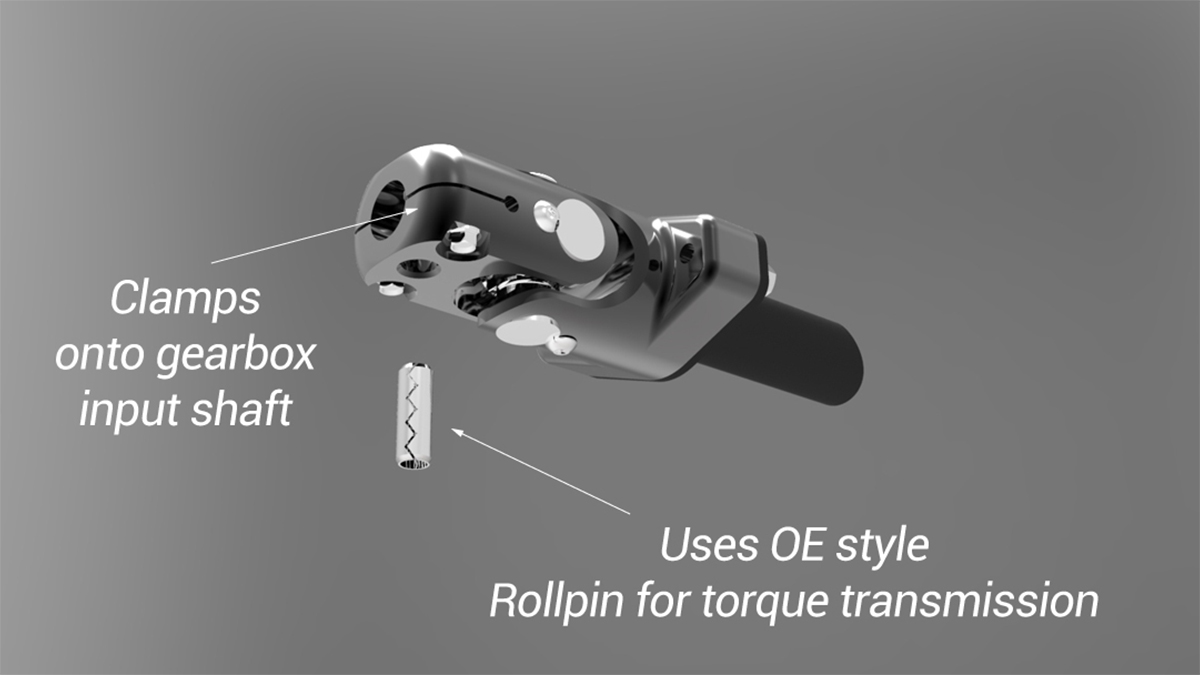

Honed’s Gear Linkage Kit replaces the factory rubber universal joint with a motorsport-style roller bearing joint along with an OE-style rollpin on the gearbox input shaft clamp for torque transmission.

Once installed, which does require cutting and re-welding the original gear linkage, an added benefit is the ability to disconnect the linkage with two bolts, reducing the time taken to remove and install the gearbox.

A hidden and often overlooked culprit in a poorly-shifting Honda is the plastic cage bush in the assembly underneath the gearstick.

When installing the Honed Gear Linkage Kit, it’s worth taking the time to install a new plastic cage bush to ensure it’s not the weak link in the chain.

It’s important to remember that even the youngest of the ‘Golden Era’ Hondas is now well over 20 years old so in addition to installing parts for improved performance, there’s real value in giving attention to areas of the car that will have deteriorated with time and use.

Differences between Honda L15a1 and L15a7

Honed’s write up on the differences between L15a1 and L15a7 engines

Solving Honda Fuel Surge

Honed’s anti-surge kit makes solving Honda fuel surge easy

Honda Fit/Jazz (GD3) performance guide

The Honed recipe for extracting the most of your your Fit/Jazz