Last weekend we headed up to the track to get some more data on the effectiveness of the air guide product. We’ve previously measured caliper temperatures at the same circuit, but this time we wanted to get more in depth and look at the temperature of the disc itself, which is critical for pad and disc performance and longevity.

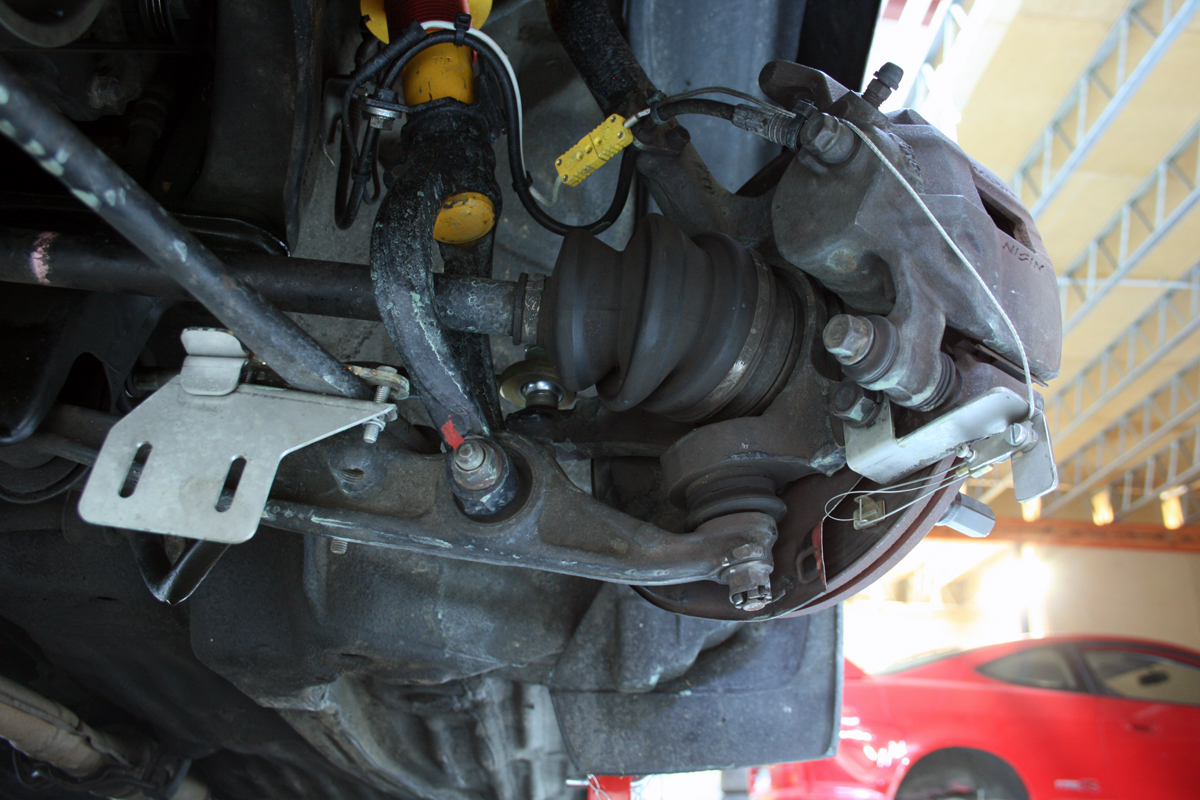

The car used for testing is our old EF Civic hatchback. It’s fairly unmodified; here’s a quick run down of the important info:

D15B twin carburetor engine

Koni sport shocks with GC sleeves and 500/450lb/in spring rates at the front and rear

ED9 CR-X disc brake conversion with 242mm ventilated front discs and discs at the rear

Hawk HPS brake pads at the front and rear

15×7″ wheels with high performance street tyres

Air guide installed on left side only

The Civic left the factory with 90ish horsepower 28 years ago and a few of those horses have gone missing since, so performance is best described as sedate. Contrary to what you might expect though this is perfect for brake testing; it allows consistent consecutive laps in terms of maximum straight line speeds and mid corner speeds, for easy data comparison.

We installed our basic data logger with temperature sensors on the two front discs. The sensors used are a K type thermocouple which gently rubs against the surface of the brake disc using a sprung bracket. Using these sensors we can log temperatures up to 850° C (1560°F). The disadvantages of this method are a small response lag as the heat transfers from the disc to the thermocouple, but given the large heavy disc with quite good heat transfer properties this is a minor effect. Similarly the small amount of heat generated by friction on the disc is insignificant compared to the heat from the disc itself when on a race circuit.

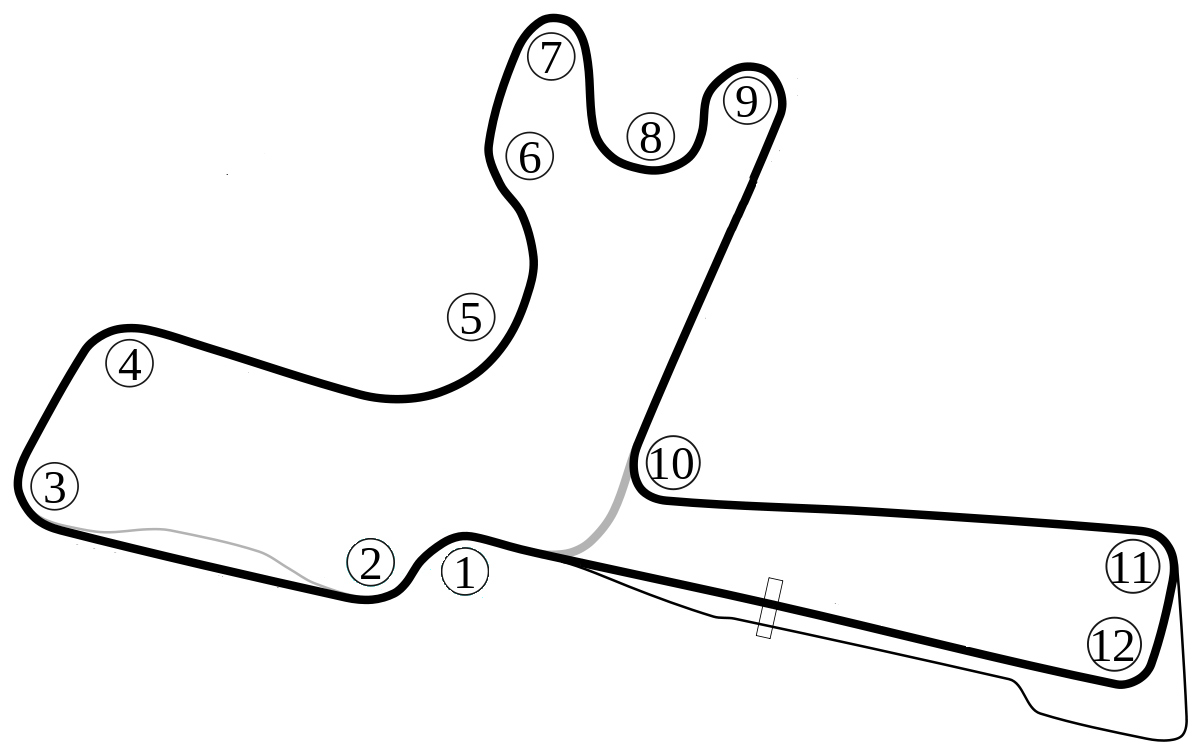

The weather at the track was hot and dry, topping out at around 35°C. Winton Raceway is a medium speed circuit with a number of lengthy braking zones, particularly at turns 1, 10, and 11; perfect for providing data to make some direct comparisons on the air guide performance. This is the layout of the circuit:

With all the equipment set up we ran a number of sessions while logging temperatures continuously. In the first sessions the air guide was installed on the left side only, then we removed it for the afternoon session to obtain control data and to eliminate any potential equipment errors.

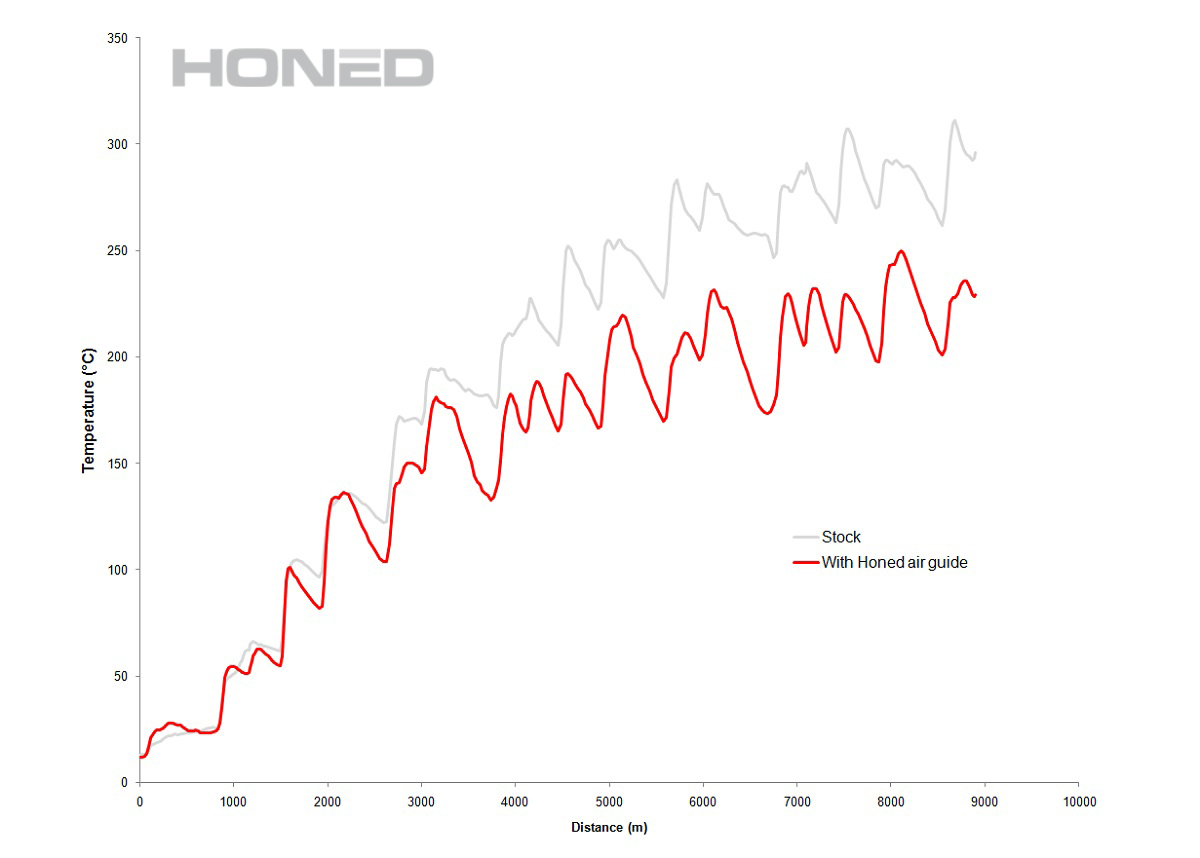

When we delved into the data it was clear immediately that the air guide gave a noticeable reduction in disc temperature. The graph below shows clearly this result:

This is a graph of a series of three laps with the air guide fitted showing the temperature of the two front discs. As you can see, over the course of the session the temperature rise of the disc without the benefit of the air guide greatly exceeds the disc being cooled by the air guide. The average temperature reduction on the last lap of the set was 62°C, or more than 20% of the average disc temperature of 280°C.

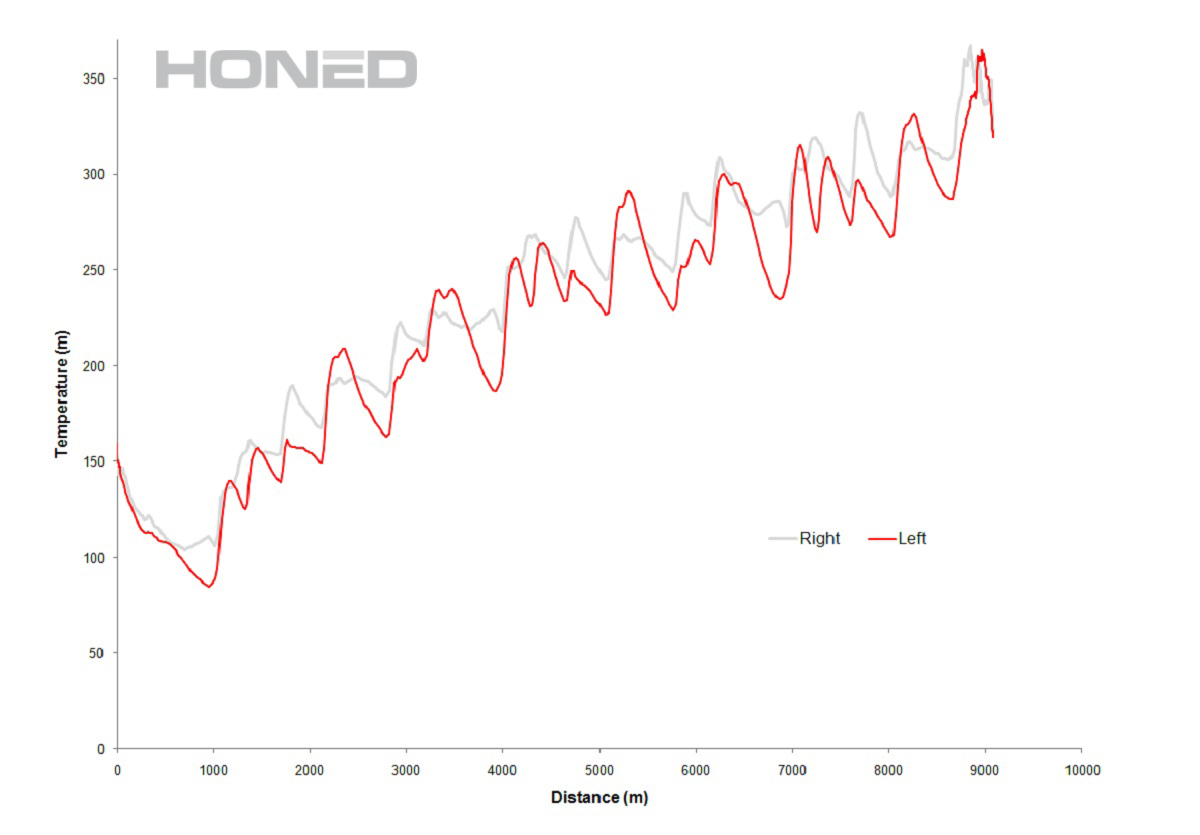

For comparison, here’s a similar set of three laps without the air guides in place.

Notice the two front discs are very consistent in temperature this time. The slightly different shaped peak and troughs of the traces are likely a result of small variances in thermocouple contact and the resulting heat transfer. With the worn discs and flexible spring thermocouple it is difficult to ensure consistent contact on both sides which is why it’s important to always verify data back to back like this.

From our testing it’s clear that the air guides are very effective providing a 20% reduction in peak temperatures on track. This significant 20% reduction will give longer pad and disc life. Furthermore for street/track cars it will allow the user to swap to a more street oriented pad compound with better road manners, without losing ultimate on track performance or risk of fade. Take a look at the air guide kit range here, and if you don’t see your car on the list feel free to get in touch so we can put your car on the development list.

Thanks to Gripshiftslide.com for providing all the pictures for this post.